Empowering Industries Enriching Growth

Unleashing the Potential of Nanomaterials

The upcoming world is going to be governed by new materials and applications derived from nanotechnology. Nanoscale materials offer multiple potential advancements across various fields such as electronics, medicine, environment, food, pigment, textiles, aerospace, and robots. These materials are capable of creating faster and smarter electronic devices, improving drug delivery systems, developing efficient energy sources, and enhancing pollution control filters.

Dravya Shakti focuses on helping researchers, research institutes and industries to harness the true potential of materials science for their purposes through its indigenously developed Dual-Drive Planetary Ball Mill – ECOTYPE and through collaboration.

Enter the realm of innovation with the exclusive commercial Dual-Drive Planetary Ball Mill – Dravya Shakti Ecotype Alpha, a cutting-edge grinding machine engineered for precision in processing metal alloys, ceramics, and composite materials, producing ultrafine nano-scale materials. These nanomaterials serve various industries, including Automotive, Pharmaceuticals, Biomaterials, Agriculture, Pesticides, Cosmetics, Pigments, Paints, Polymers and more.

The DDPBM Dravya Shakti Ecotype Alpha accelerates drug discovery by markedly reducing synthesis times.

Successfully running at various prestigious institutes for research on material sciences.

The machine utilises the principles of DEM to model the interactions and behaviour of discrete particles during mechanochemical reactions. This simulation could aid in understanding the underlying physics and optimising reaction conditions. It could be a simulator also to the various scenarios of material mixing.

Ecotype Alpha has the capability to apply mechanical forces in multiple directions (e.g., compression, shear, and torsion) to mimic real-world scenarios and study complex reactions.

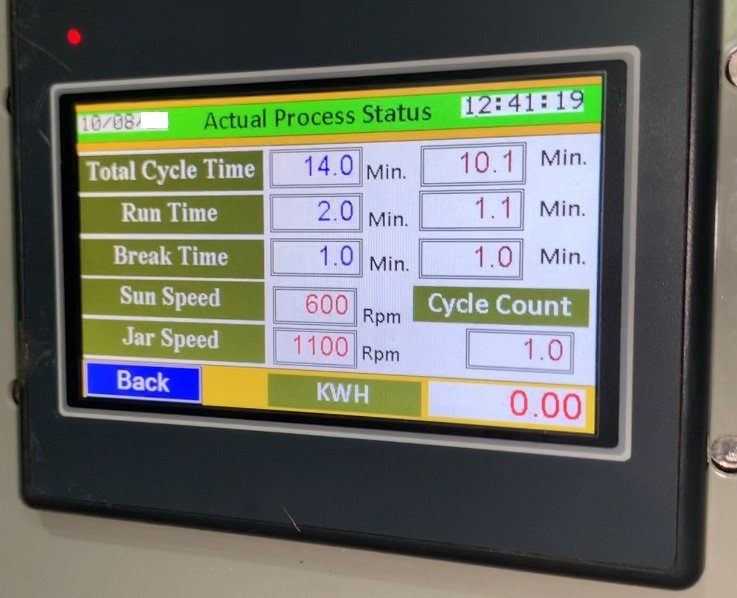

Users can program the transmission ratio according to the specific materials being processed. The transmission ratio is variable to infinite possibilities with clockwise and anti-clockwise directions: 1:-2, 1:-2.5, 1:-3 or any can be achieved within the above jar or sunwheel speed range.

To ensure accurate and reproducible experiments, the machine features high-precision motion control systems that allow researchers to precisely set and adjust mechanical parameters.

The machine could have automated sample handling systems, allowing researchers to load samples and initiate experiments with ease. We shall understand your requirements and design the SPM for your purpose

The pursuit of nanotechnology in academia fuels scientific advancements that contribute to humanity’s understanding of the fundamental building blocks of matter, pushing the boundaries of what is scientifically possible.

Our machines have been instrumental in publishing six patents & various papers in international journals, related to material science. This background gives us the confidence that we can help you with your objectives in the least possible timeframe.

Embark on an industry renaissance powered by Nano Wonders. See how nano integration propels innovation across sectors, from manufacturing to healthcare. It’s not just about evolution; it’s about revolutionising the industrial landscape.

As the world rapidly embraces the revolutionary potential of nanomaterials, businesses across diverse industries are seeking innovative solutions to translate cutting-edge research into successful real-world applications. However, translating nanotechnology from lab to market presents unique challenges that require specialized expertise and efficient management.

We are a leading Knowledge Process Outsourcing (KPO) provider specializing in nanomaterials project implementation. Our team of seasoned scientists, engineers, and project management professionals brings exceptional depth and breadth of experience across a multitude of industrial sectors.

We can reduce your capital expenditures or provide capital expenditure benefits. Various government schemes are available for establishing research and development (R&D) and R&D-based production structures on a case-by-case basis.

The C3PC Research Foundation is a non-profit organization committed to fighting childhood cancer. Their mission is multifaceted, encompassing:

The field of cancer and nanoparticle science holds immense potential for improving diagnosis, treatment, and prevention of this disease. While challenges remain, ongoing research and development promise exciting advancements in the years to come, C3PC Research Foundation and Dravya Shakti products offering hope for a future where cancer is no longer a death sentence.

Imagine a material so versatile, it strengthens buildings, delivers life-saving drugs, and even enhances the beauty of everyday products. Nano-scale Silica powder, composed of incredibly small silicon dioxide (SiO2) particles, is no longer a futuristic dream but a tangible reality with far-reaching benefits for both industry and humanity.

Healthcare Innovations:

Strength and Sustainability in Construction:

Industry Benefits – A Ripple Effect:

Human Benefits – A Sustainable Future:

Silica nanopowder is just one example of the transformative power of nanotechnology. By harnessing the potential of these tiny particles, we can build a stronger, healthier, and more sustainable future for all.

Are you ready to join the nanorevolution? Contact us today to discuss how silica nanopowder can benefit your industry and contribute to a better tomorrow.